LDS (Laser Direct Structuring) is a process whereby an antenna can be designed and produced onto a 3-dimensional plastic carrier. This carrier can be a separate plastic entity or an existing integral part of the customer’s product’s housing.

It has been many years since the rise of TWS earphones, and its market has been growing rapidly. Nowadays, with the development of earphones, the TWS earphone market has also begun to enter a serious competition situation. Therefore, higher requirements are put forward for the antenna, which is one of the core components of TWS earphone products. How to reduce size, weight, cost, and assembly risk has become an increasingly important project for antennas. The increasingly mature LDS technology is widely favored by Product Designers and Structure Engineers for its small size and flexible design. It is also favored by Quality Engineers and Purchase Engineers because of its stable quality and high cost performance. As LDS antenna is the specific application of the TWS Bluetooth antenna, what are the advantages?

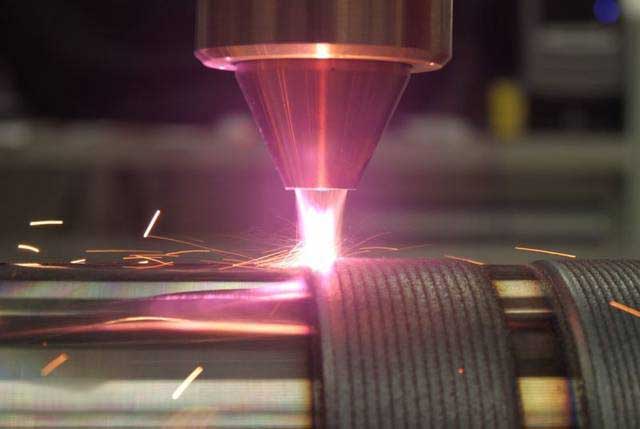

In response to the above problems, we interviewed Manager Zhu, a senior antenna expert from SHENZHEN TOP-LINK TECHNOLOGIES CO.,LTD.— Mr. Zhu, he introduced that the full name of LDS is Laser Direct Structuring, which refers to the use of CNC lasers to directly print circuit patterns on the surface of plastic components. The technology of forming a circuit interconnection structure on the three-dimensional surface of a three-dimensional workpiece. The LDS material is a modified plastic containing an organic metal compound. After laser induction, the metal particles in the plastic are activated and precipitated, and the particles are used as the activation center of the metal plating.

Compared with FPC antennas, LDS antennas have higher space utilization. The biggest disadvantage of FPC is that it cannot adapt to complex three-dimensional structures. And LDS can use laser to etch on the three-dimensional structure, and there is almost no structural obstacle. In addition, LDS has high etching precision and uses the plastic parts of the product for operation, so there is no problem of assembly risk and performance consistency.

SHENZHEN TOP-LINK TECHNOLOGIES CO.,LTD. specializes in the design and manufacture of LDS antennas. Our advantages are as follows:

1. With a professional antenna development team, we can assist customers to complete the comprehensive problems of antenna design and product stacking;

2. With advanced LPKF equipment, the highest precision can reach 25μm;

3. Authorized by LPKF, there is no patent risk for product export;

4. Professional and complete LDS manufacturing management system to ensure high FPY and reduce costs;

5. With self-developed automatic laser carving and RF testing equipment, production capacity meets customer requirements.

6. with Via hole design and manufacturing experience, we can make product surface treatment easy.