In today’s increasingly pursuit of miniaturization and portability in electronic products, how to achieve complex functions in limited space and ensure safety and stability has become the core challenge faced by R&D engineers. Traditional connection methods are often limited by spatial layout and assembly difficulty, making it difficult to meet the demands of modern consumer electronics and smart medical devices for high-density and high reliability connections. Top-link has provided a breakthrough solution to this problem with innovative wire bonding and pin connection technology, redefining the connection standards for miniaturized devices.

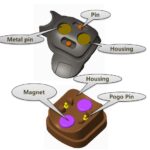

Top-link Pogo Pin Wire-welding Connection

Top-link ‘s wire pin design adopts a combination of axial wire and side wire, with one end firmly connected to the PCBA or connector and the other end efficiently docked with the opponent’s PAD. This design not only greatly enhances the flexibility of connections, but also provides terminal engineers with more diverse layout options. In the field of consumer electronics, whether it is ultra-thin smartphones, mini wireless headphones, or hinge modules of foldable screen devices, wire bonding pin technology can achieve stable signal transmission and power supply in a very small space, while reducing impedance and ensuring that the device maintains high efficiency performance during long-term use.

In the field of smart healthcare, reliability is a key indicator related to life and health. Top-link’s wire bonding technology is widely used in portable monitors, implantable medical devices, and high-precision surgical instruments due to its high precision and strong anti-interference ability. For example, in the microcircuit of a pacemaker, the low resistance characteristic of the solder pin can reduce energy loss and extend device life; In the flexible circuit of the endoscope, its excellent shock resistance and bending resistance can adapt to complex internal environments, ensuring zero errors in signal transmission. The application of this technology not only improves the performance limit of medical equipment, but also provides a solid guarantee for patient safety.

Compared with traditional welding or insertion methods, Top-link’s wire-welding Pin technology significantly optimizes the assembly process. Its modular design allows for quick installation and debugging in the production line, significantly reducing production costs and labor hours. At the same time, the compact structure avoids the occupation of redundant space, creating more layout possibilities for other key components such as batteries and sensors, and helping products achieve the ultimate goal of “small but strong”.